Choosing tools for repairing dents without painting (PDR) can be a real challenge, especially for beginners in this field. A variety of tools and accessories can be confusing, but choosing the right one makes the work process much easier.

Basic tools for PDR

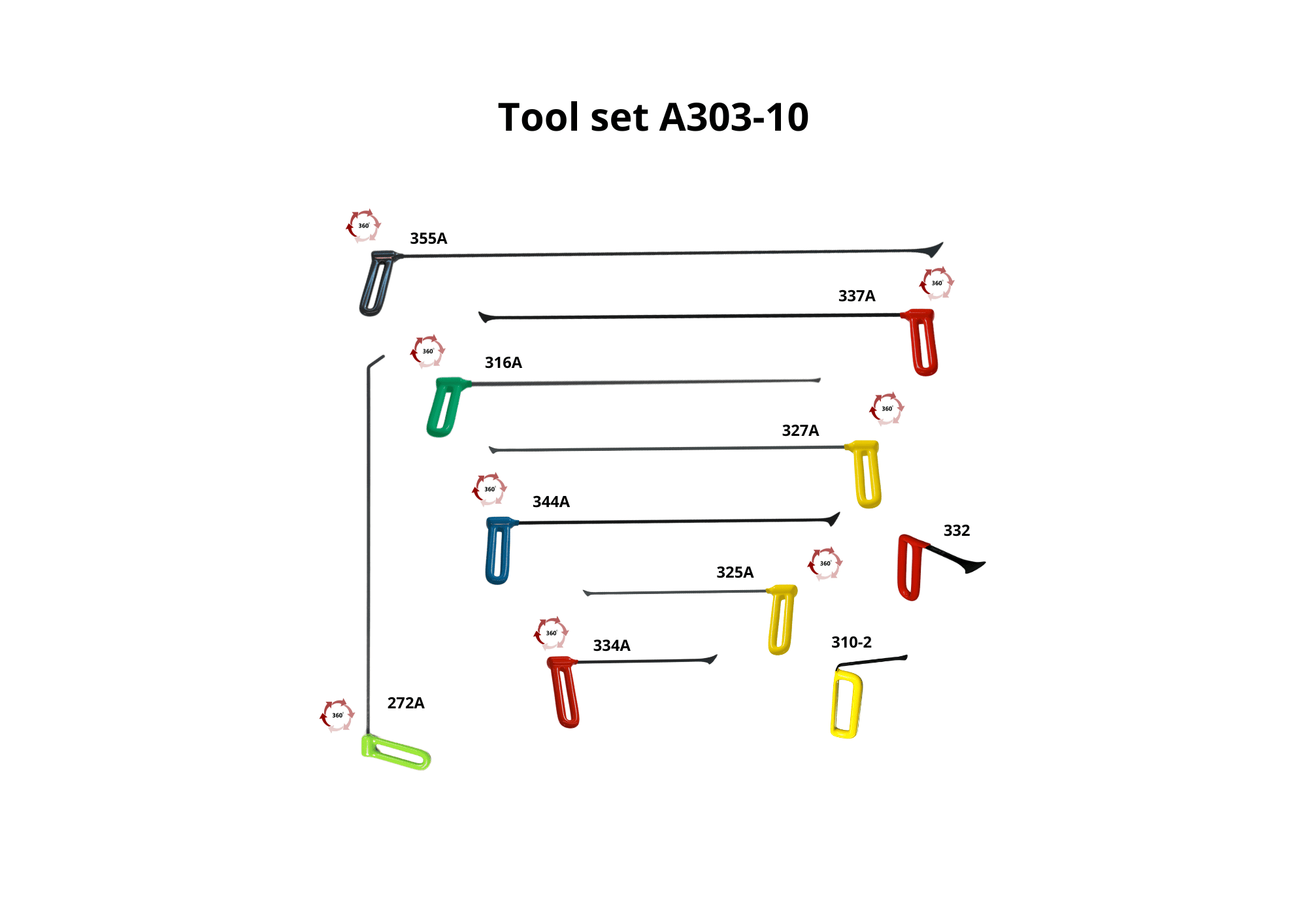

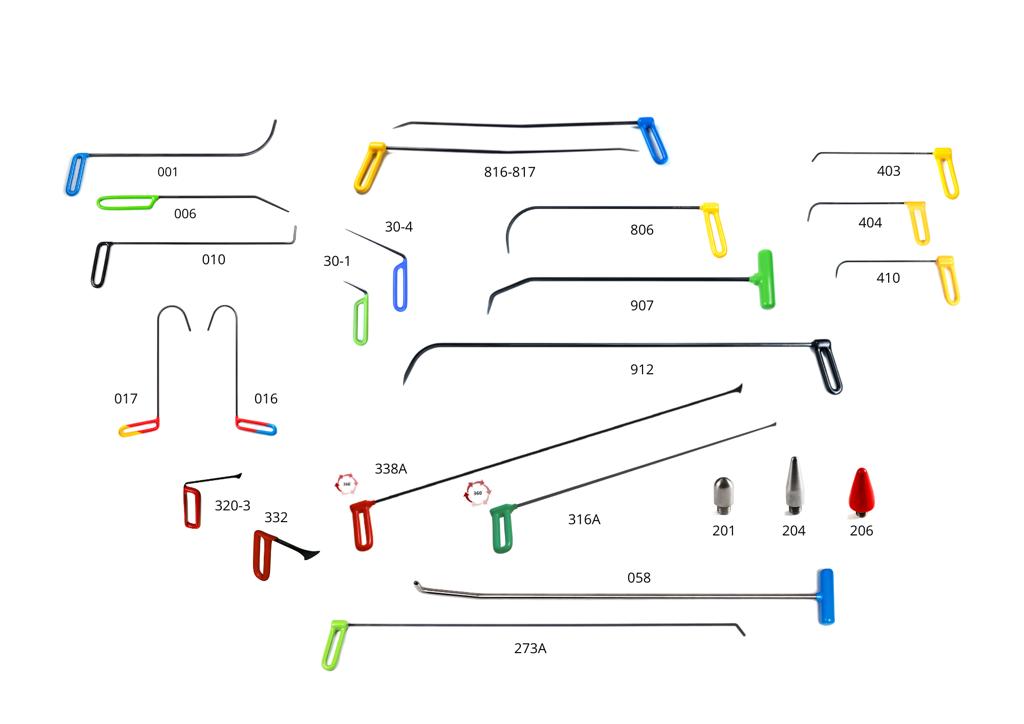

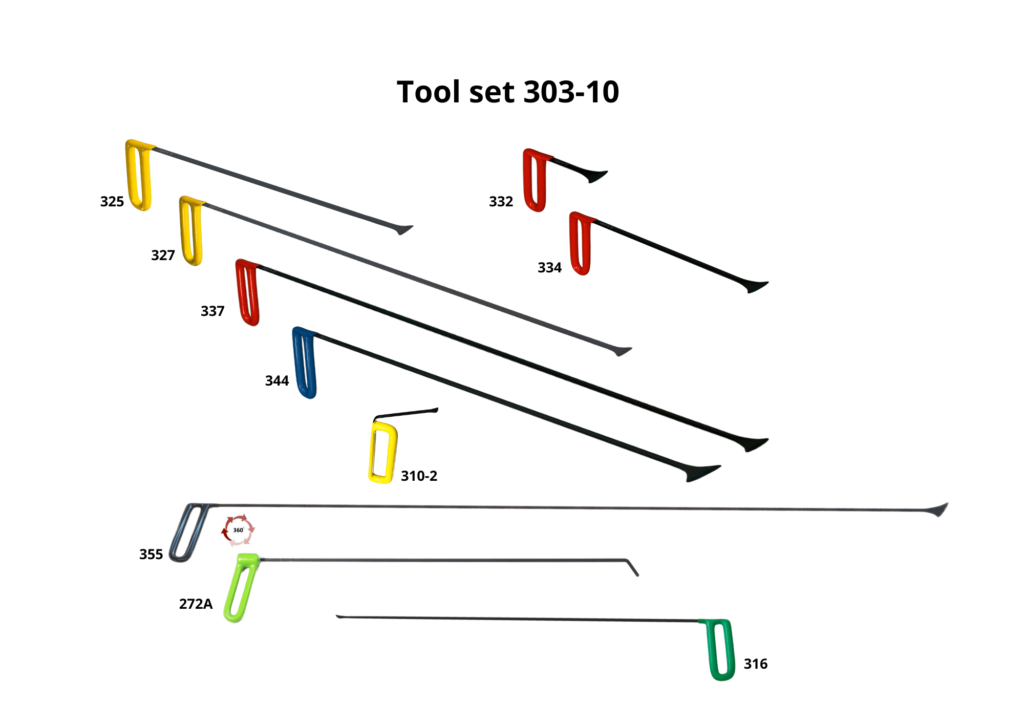

The first step to successfully repairing dents without painting is to purchase basic tools. One of these tools is the professional pdr tool kits. These kits include all the necessary tools to help you get started. They usually include various hooks, clubs and other devices that will help you straighten the dents on the car.

For example, a good set may have hooks of different sizes and shapes, which allows you to work with dents of varying depth and complexity. Also, special hammers and rubber tips are often found in such kits, which help to carefully straighten the dent without damaging the paintwork of the car.

An equally important tool is the pdr flat bar. This flat bar is used to straighten dents in hard-to-reach places such as car doors and roof. It is characterized by strength and flexibility, which allows you to work with various types of metal and shapes of dents. The flat bar can be used to work with large surfaces, ensuring uniform pressure and minimizing the risk of additional damage.

Another important tool is the glue gun and glue rods. This tool is used to fix dents without access to the back of the panel. Apply glue to special fungi, which are then glued to the dent, and with the help of a special slider, the dent is pulled into place.

Coverage of PDR work

Lighting plays a key role in the dent repair process. Good lighting allows you to see all the details of the damage and correctly assess how best to fix it. The pdr lamp is ideal for this. This lamp is specially designed to work with dents, providing bright and uniform light. It helps the master to accurately determine the boundaries of the dent and control the straightening process.

Some lamps have adjustable brightness and the ability to change the lighting angle, which allows you to adjust them to specific working conditions. It is also important to take into account the mobility of the lamp – the presence of a magnetic base or mounting will help you easily install it anywhere on the car body.

For those who work in confined spaces, there are compact portable lamps that can be easily carried and installed in the right places. Such lamps are usually equipped with batteries, which makes them self-contained and convenient to use.

What to consider when choosing tools

There are several important factors to consider before purchasing PDR tools:

- The quality of the materials. Tools must be made of strong and durable materials to withstand the load and not break during operation. For example, stainless steel or high-strength aluminum will be an excellent choice for basic tools.

- Ergonomics. The tools should be convenient to use in order to reduce the fatigue of the master and increase the accuracy of the work. The handles of the tools should be covered with soft materials to prevent slipping and provide a comfortable grip.

- Complete set. It is important that the kit contains all the necessary tools to perform various types of work. The presence of various nozzles and tips allows you to work with dents of various shapes and sizes.

- The price. It is not always worth choosing the cheapest tools, as they may be short-lived. It is better to choose the optimal price-quality ratio. Sometimes it is worth investing in more expensive tools that will last longer and ensure high quality work.

Additionally, it is worth considering the purchase of specialized accessories, such as adjustable tool holders, which will help you customize them to specific working conditions. For example, telescopic holders will help you reach the most inaccessible places without having to disassemble half of the car.

In order for the work to be convenient and efficient, it is important to organize your workplace correctly. This is where the PDR shop comes to the rescue. The well-equipped workshop includes all the necessary tools and fixtures, as well as convenient work surfaces and storage spaces. An organized workspace allows you to perform work faster and better, which is especially important when there are a large number of orders.

Conclusion

Choosing the right tools for repairing dents without painting is the key to successful work and satisfaction of your customers. Following our recommendations, you will be able to choose high-quality and convenient tools that will help you cope with any tasks. Do not forget also about the importance of good lighting and workplace organization, because this is no less important for high-quality work.